Author Archives: typritchard

We have a line!

Full house

Ghost (september 2)

Quote

Today seemed to be like any other day. Mike and I arrived and walked into the chamber of sound. I started with resupplying some business cards, picking up garbage, answering questions, not much new. I grabbed the drills and began to open up crates in search of some extra cellulose, some how it keeps disappearing. I have noticed people MUST touch the wall sections, I don’t blame them. I found the cellulose and as soon as I pulled it out of the crate I was approached by a man. He wore small round glasses and a black leather beret. The man had an haggard beard with twisted once-upon-a-time blond hair. The lines on his face told the story of time. He began casual enough asking a few questions about the house nothing out of the ordinary but soon the story began to play out. He described his life, things he had seen and I was genuinely interested. Claiming to be a professor at Berkeley he told stories of technology, music, and chemistry. The details and descriptions where dense but from my point of view deceptive. Soon this was no ordinary encounter and two and a half hours passed. Ultimately the conversation ended and I asked for his name, he asked, “Does it matter?” I said “No” as I stepped away. I still don’t know how I feel about the encounter but one thing is for sure, I wont forget it, and maybe this was the point.

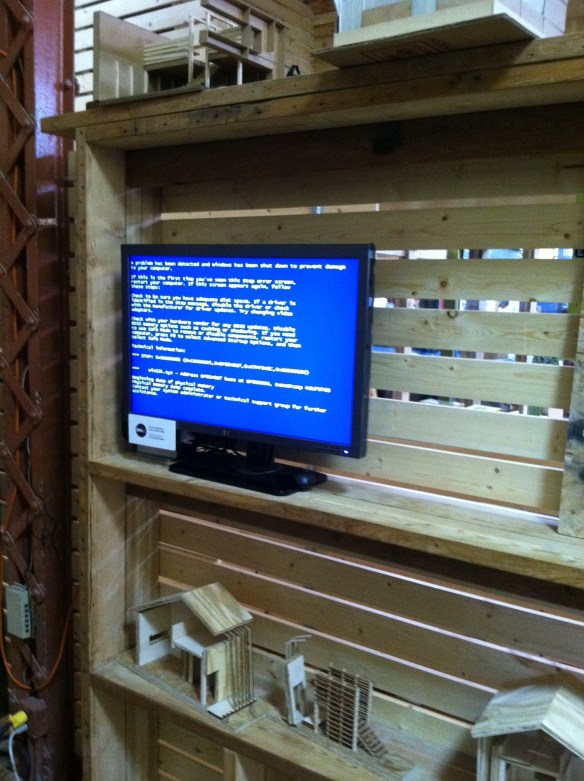

Windows

Fixed

31 August, 2011 22:17

31 August, 2011 22:15

31 August, 2011 22:14

burlap+light

23 August, 2011 01:38

23 August, 2011 01:37

The inspectors are happy now.

Ribbons

L-C-A (august 18)

Quote

On the car ride to the fair grounds I was kind of dreading today. All the trim work I put up yesterday might need to be taken down because of a detail that was not fully developed. I slung my coffee thermos around my shoulder and prepared for a day of redo. I starting work with Chris A. again today and we discussed the LED light strip detail. I was really excited to see the lights. We came up with a solution but held of on trimming until we got the OK. We then, in a mad dash, finished up the wall behind the bench with scrap richlite and cedar stocks. It looked really good. After that I finished wiring up the lights and we ‘tested’ the LED light strips which worked spectacular. It was a really intense material. A ribbon of light rose from a crevice in the trim, I was happy. We had a lot of visitation today and random pictures and interviews. It was fun to see others interested and excited about our work. Lights, Camera, Action. I made my way outside and helped Brittany out with here wine bottle concrete. It was amazing. We got to 800 grit and that was that the day ended.

Scatter (august 17)

Quote

Today was all over the place. Main objective: Trim work. Chris and I worked a lot today on the richlite trim work but we paused separated and worked on other projects throughout the day. The wall got insulation, the redwood was finished, and the gabions were on a production line. Every bit was moving. After a while the electrician Brent showed up and we discussed various things as he buttoned up what was left. We were all in the cabin taking a vote on the loft when all of the sudden three electrical inspectors were walking around having one of the most difficult discussions I had ever been witness to. After all of the options were discussed and the inspectors left we juiced the house. Lights were on and outlets worked. It was a fast and rewarding day.

Sturdy (august 16)

Quote

We all walked in today eager to start. I started work on the redwood decking and was soon joined by John and Lyle. John cut, I nailed and Lyle was the puzzle master. They continued as I shifted to work with Andrew who I could tell wasn’t happy today. I know his gabions were not turning out quite like he envisioned but he soon figured out a method. By filling them in place they did not bend or morph shape, the problem was however moving mass amounts of cleaned rock. Andrew started by making a filtered bucket and washing one bucket moving into another, then to the gabions which were on the absolute other side of the progress building. This was going to take days. I decided to stab holes in the large tote and use it as one giant filter bucket, worked perfectly and after the rock was washed I forked it back over and set the pallet right next to the gabions, problem solved. After that a robot engineer, aka: guy who has installed an air exchanger before, showed up and helped with the robot in a box. After a while Chris A. and I were starting trim work, but first the sturdy table. Chris was screwing some 2×2’s to a piece of plywood and said “I haven’t made a lot of tables.” I think I am beginning to tell when he is messing with me, but we cross-braced it and made one of the best table saw tables around. We cut and trimmed until quitting time.